Your Trusted Partner for Advanced Coiled Tubing Solutions in Turkey

In the demanding landscape of modern oil & gas, geothermal, and industrial well intervention, efficiency, safety, and operational excellence are non-negotiable. LINDER ENDÜSTRİ DIŞ TİCARET LİMİTED ŞİRKETİ stands as the premier and official supplier in Turkey for state-of-the-art Coiled Tubing Equipment and systems from the world’s leading manufacturers. We specialize in direct and official imports, ensuring genuine quality, certified performance, and comprehensive technical support for your most mission-critical projects across the Turkish market.

Harnessing Continuous Innovation: The Power of Coiled Tubing Technology

Coiled Tubing (CT) technology represents a revolutionary leap in well intervention, replacing traditional jointed pipe with a continuous, high-strength steel tube spooled on a reel. This allows for rapid, uninterrupted deployment and retrieval, drastically reducing operational time and enhancing safety. Modern CT units, with diameters ranging from 0.75″ to 5″ and yield strengths up to 120,000 psi, enable complex operations—from precision drilling and logging to efficient stimulation and decommissioning—at depths exceeding 9,000 meters.

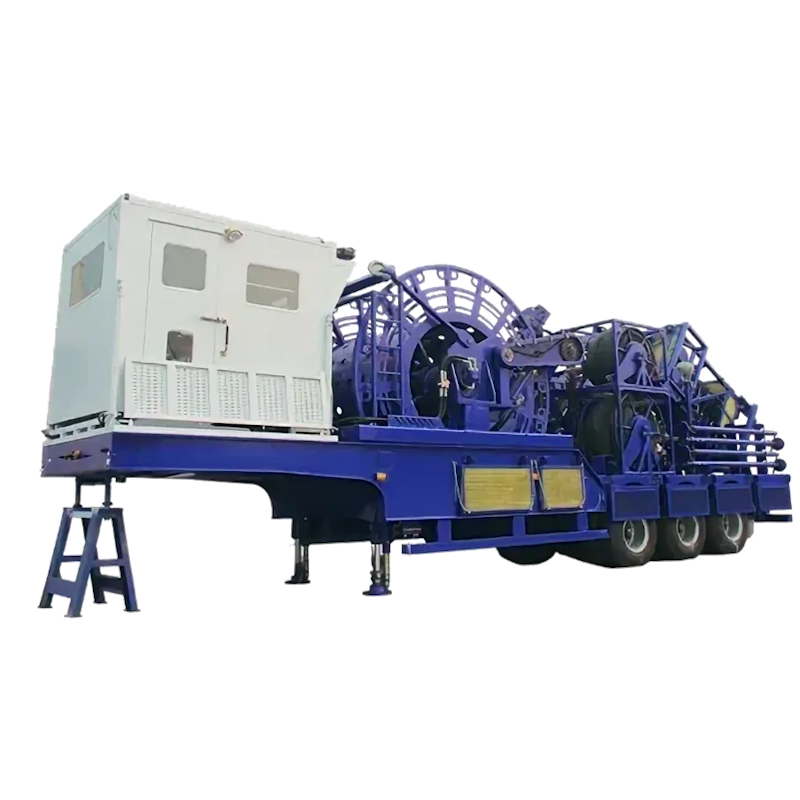

LINDER Delivers Complete, Mission-Critical Coiled Tubing Systems

Success hinges on a perfectly integrated system. As your strategic partner in Turkey, LINDER provides end-to-end solutions, sourcing and supplying every critical component from globally renowned brands.

The Core System Components We Supply:

Reel Unit: Engineered for maximum durability and safe handling, this system stores and transports the continuous tubing under all field conditions.

Injector Head: The high-power unit that provides precise force to run and retrieve tubing into pressurized wells, ensuring accurate depth control and operational integrity.

Control Cabin & Power Pack: The operational nerve center and its robust hydraulic/electric power source, designed for intuitive control and unwavering reliability in harsh environments.

Advanced Well Control & Pressure Equipment

Safety is paramount. LINDER supplies complete, certified Well Control Packages, including:

Blowout Preventer (BOP) Stacks: Multi-ram systems (such as quad BOPs) for secure shearing, sealing, and wellbore isolation.

Stripper & Lubricator Assemblies: Essential for maintaining a dynamic seal around the moving CT, allowing safe tool entry and change-outs under pressure.

Unlock Superior Operational Advantages with LINDER

Choosing LINDER as your Coiled Tubing partner in Turkey translates into direct, tangible benefits for your bottom line and operational safety.

Key Benefits for Turkish Industries:

Live-Well Intervention Capability: Perform operations without killing the well, preserving vital reservoir pressure and integrity.

Enhanced Safety & Reduced Risk: The continuous pipe eliminates connection-related hazards, while our top-tier control equipment ensures the highest safety standards for personnel and assets.

Unmatched Operational Efficiency: Achieve rapid trip speeds and continuous circulation, significantly reducing job cycle times and associated costs.

Proven Cost-Effectiveness & ROI: Benefit from lower mobilization costs, faster project completion, and reduced total intervention expenses.

From Global Innovation to Your Local Project in Turkey

The evolution of coiled tubing, from its historical origins to its current high-tech status, is now directly accessible for Turkish industry through LINDER. We bridge the gap between global manufacturing excellence and local application expertise. Our commitment extends beyond supply to include in-depth engineering consultation, project-specific planning, logistics management, and dedicated after-sales service.

Partner with LINDER—where global technology meets reliable local partnership. Empower your projects with the definitive edge in Coiled Tubing solutions.

Country Manager : Asli CIVAN

Country Manager : Asli CIVAN  Characteristics

Characteristics